Company Profile

The company is headquartered in Fornacette Calcinaia (Pisa) and is composed of several establishments where several activities take place such as:

- Raw materials inventory and cutting tube (2,000 sqm)

- Department cold forming of tubes and plates, bending pipe, machining machine tool (2,000 sqm).

- Prototyping and small series production floor (2,000 sqm)

- Equipment department, Metrology room (800 sqm)

- Automatic assembling frames and various special tube and sheet, administrative offices, logistics and planning. (5000 sqm)

Download brochure

Corporate Video

Corporate Video

Corporate Video

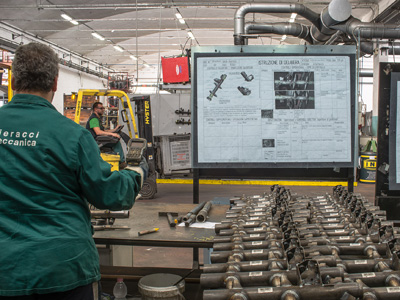

PHOTOS

The present period is characterized by an excess of offer regarding the demand: in fact the request for technological innovation is very strong and the pressure of been global is also supported.Therefore, to afford this complex market it is essential for the company having a clear and precise strategy based on optimization of product development, manufacturing efficiency and quality with which to satisfy itself and the customer.The trump card of the success of Pieracci Meccanica has been and continues to be the quality of their products combined with technology development and production to meet market needs and customer satisfaction.

The company is ISO 9001:2000 certified.

Flexibility and productivity are two concepts that were previously considered always in opposition.

Today, however, customers are increasingly demanding these features together. In order to achieve appropriate solutions to customer requirements, a company

must have an adequate organizational structure in terms of design, manufacture and service.

Currently the main activities are:

PROTOTYPE, CONSTRUCTION, INSTALLATION AND ASSEMBLY OF PARTS OF CYCLE, MOTORCYCLE AND SCOOTERS SUCH AS:

- Frames

- Handlebars

- Stands

PROTOTYPE CONSTRUCTION AND ASSEMBLY:

- Exercise equipment

DESIGN AND CONSTRUCTION:

- Moulds and specific tools

- Welding masks

- Equipment for bending